RO Systems

#நீரின்றி அமையாது உலகு

World Class Advanced Technology

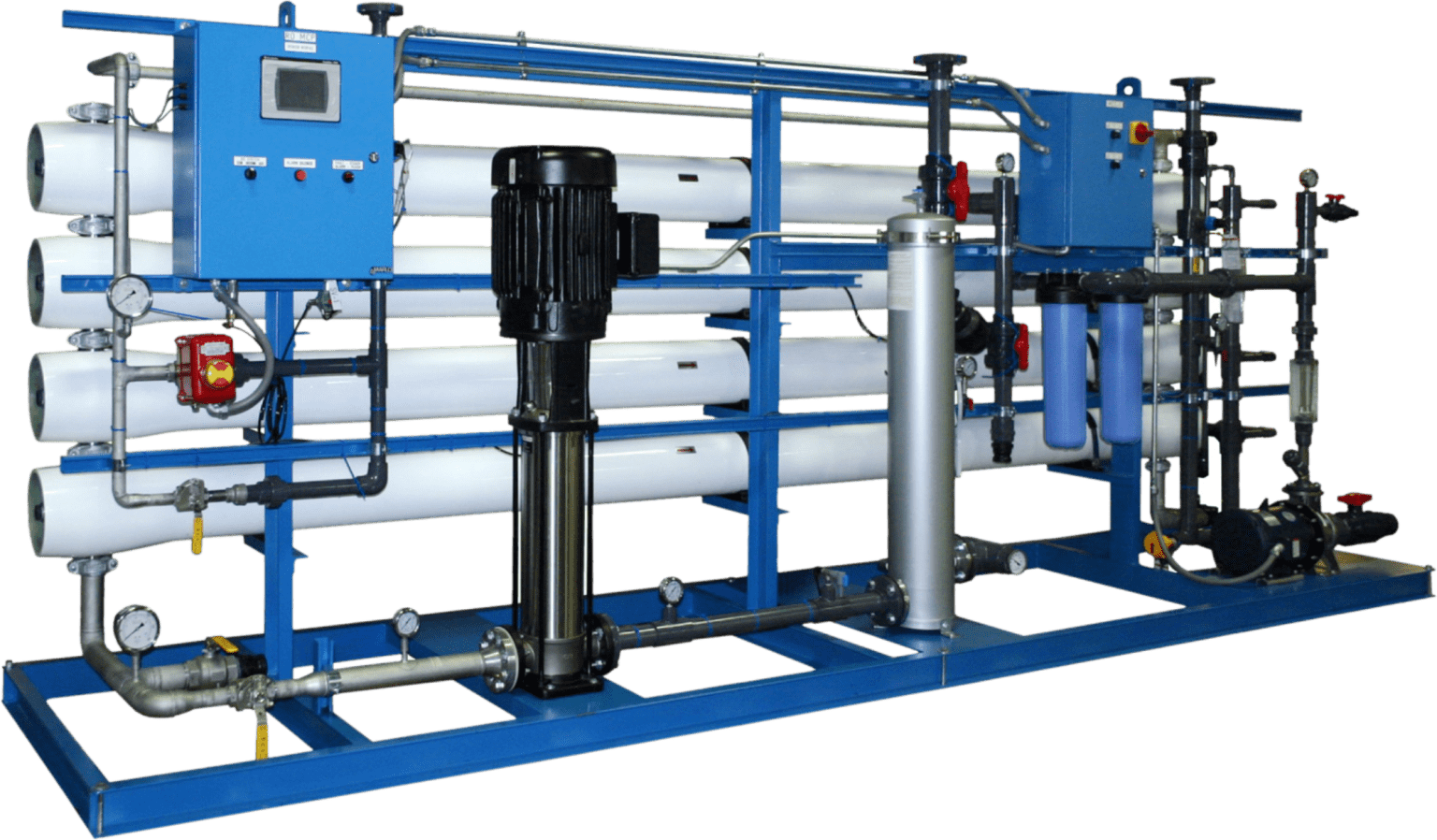

Industrial RO Systems

Very low TDS water which is free from particulate, organic & colloidal matters.

Ranges from 150 LPH to 20,000 LPH

A production facility where the reverse osmosis process is carried out is known as a RO plant. By pushing water over a membrane,

RO is a typical technique for purifying or desalinating polluted water.

RO Plant

These facilities must figure out how to use less energy, sustainable energy sources, enhance the desalination process, and innovate in the field of waste management to deal with the trash. Reverse osmosis water purification systems, also known as self-contained reverse osmosis water treatment plants, are typically utilised in a military setting.

RO System

Pre-treatment procedures for RO plants must include softening, dechlorination, and anti-scalent treatment. After pre-treatment, water is forced under high pressure through a semi-permeable membrane, which traps all impurities while allowing pure water to pass through.

PRINCIPLE

Osmosis is a natural process. When two liquids of different concentration are separated by a semi permeable membrane, the fluid has a tendency to move from low to high solute concentrations for chemical potential equilibrium.

Osmosis describes how solvent moves between two solutions separated by a permeable membrane to reduce concentration differences between the solutions. When two solutions with different concentrations of a solute are mixed, the total amount of solutes in the two solutions will be equally distributed in the total amount of solvent from the two solutions. Instead of mixing the two solutions together, they can be put in two compartments where they are separated from each other by a semipermeable membrane. The semi permeable membrane does not allow the solutes to move from one compartment to the other, but allows the solvent to move.

RO Plant

These facilities must figure out how to use less energy, sustainable energy sources, enhance the desalination process, and innovate in the field of waste management to deal with the trash. Reverse osmosis water purification systems, also known as self-contained reverse osmosis water treatment plants, are typically utilised in a military setting.

RO System

Pre-treatment procedures for RO plants must include softening, dechlorination, and anti-scalent treatment. After pre-treatment, water is forced under high pressure through a semi-permeable membrane, which traps all impurities while allowing pure water to pass through.

PRINCIPLE

Osmosis is a natural process. When two liquids of different concentration are separated by a semi permeable membrane, the fluid has a tendency to move from low to high solute concentrations for chemical potential equilibrium.

Osmosis describes how solvent moves between two solutions separated by a permeable membrane to reduce concentration differences between the solutions. When two solutions with different concentrations of a solute are mixed, the total amount of solutes in the two solutions will be equally distributed in the total amount of solvent from the two solutions. Instead of mixing the two solutions together, they can be put in two compartments where they are separated from each other by a semipermeable membrane. The semi permeable membrane does not allow the solutes to move from one compartment to the other, but allows the solvent to move.

Preserve water, preserve life.

Commercial RO System

Important Notes for Selection :

- These are standard plants, however one should select the RO plant with an application and analysis test report.

- The Eco model is best suited for the water containing lower TDS ( < 300 to 500 ppm)

- There is no guarantee and Warranty for any Consumables and RO membrane in every sector. As it totally depends on the quality of raw water.

- It is desirable that raw water is free from – O&G, Chlorine, Turbidity, Manganese, Iron, Silica etc as these elements may deteriorate the life of the membrane.

Applications

- Drinking Water purification

- Water and waste Water purification

- Food industry

- Car washing

- Hydrogen production

- Reef aquariums

Drinking Water purification

Around the world, household drinking Water purification systems, including a reverse osmosis step, are commonly used for improving Water for drinking and cooking.

Water and waste Water purification

Rain Water collected from storm drains is purified with reverse osmosis Water processors and used for landscape irrigation and industrial cooling, as a solution to the problem of Water shortages.

Food industry

In addition to desalination, reverse osmosis is a more economical operation for concentrating food liquids (such as fruit juices) than conventional heat-treatment processes.

Car washing

Because of its lower mineral content, reverse osmosis Water is often used in car washes during the final vehicle rinse to prevent Water spotting on the vehicle.

Hydrogen production

For small scale production of hydrogen, reverse osmosis is sometimes used to prevent formation of minerals on the surface of electrodes.

Reef aquariums

Ordinary tap Water can often contain excessive chlorine, chloramines, copper, nitrogen, phosphates, silicates, or many other chemicals detrimental to the sensitive organisms in a reef environment.

Advantages

Our Reverse Osmosis Plant have the following Advantages :

- Actively rejects ions and contaminants.

- Reduce Water that meets the most demanding specifications.

- Allow the membrane to continually clean itself

- Higher pressure from the pump to push the fluid through the membrane.

- Capable of rejecting acteria, salts, sugars, proteins, particles, dyes and other constituents.

- Works in various molecular weights.